I tried this 500-series frame, and while it is good for the price, it is still the worst I've had in my hands. The other ones I know are the Wes Supercarrier II and the Fredenstein Bento 10.

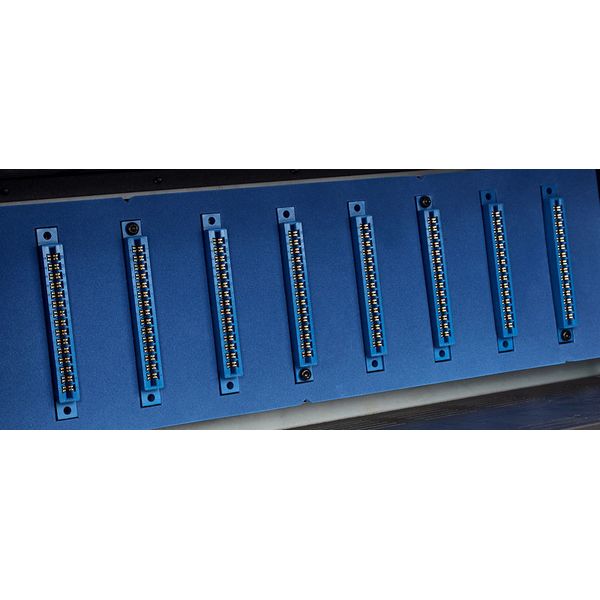

Electronically, I can't complain. I didn't notice any noise, and the quality of the connectors seems fine.

The problem comes with the build.

First of all, the width of the unit, while within tolerance, is a bit above average. And since one of my racks, while within tolerance too, is a bit narrower than average, the L10 couldn't fit in that rack. I only ever had that problem with one other piece of rack gear - and I've played with a lot.

Then, maybe I've got a bad sample, but the assembly seemed sloppy :

1. The markings on the back were printed at an angle. Not a big deal, but it doesn't inspire confidence.

2. The partition plate, between the power circuits and the bay, wasn't in place or straight, and encroached on the 10th slot. I had to force it into place. It required a hard push, and it still wasn't very straight after that.

3. Maybe because of the above, the modules, when in place, weren't perfectly parallel to each other, giving the filled frame somewhat of a "crooked teeth" look.

4. The depth is such that the modules' connectors barely touch the frame's connectors. The contacts are working, but by a hair's width.

5. The height is shorter on one side of the frame. Not to the point that is shows, but some modules have to be pushed very hard into place in the rightmost slots, because the available height is too tight.

All the above may just be bad luck and a bad sample, but then there's this:

6. The metal is too soft for threads. After driving screws a couple of times, or even just one time if you're not careful, the thread becomes loose and future screws can't be tightened very well anymore. (I know this is the case with all frames, but never to this extent!)

Will I keep it ? Yes, sure, it works. I'll keep it at least until all the screw threads are ruined.

Would I recommend it ? Not really, no.