5. Differences

Let's start with the bow stick:

The bow stick, under relentless stress during play, requires durability without permanent bending.

Wood types are natural products and vary in quality. So, if you have a very inexpensive bow, don't expect it to be made of the finest material. The best suited and widely used woods are hardwoods like Snakewood, Pernambuco, or various types of Brazilian woods.

The newer player on the block? Carbon fiber bows, available in different quality grades, including Composit—combinations of carbon and other materials like plastics.

Ipè, Massaranduba, etc.

The term "ironwood" encompasses many tropical tree species. It's a very dense wood, prized for its extreme hardness and density.

Snakewood (Brosimum guianense)

Technically belonging to ironwood, this wood gets its name from its special grain resembling snake skin. It's a very noble wood, yet very challenging to work with. A bow made from this wood is very heavy and therefore not recommended for beginners.

Snakewood

Pernambuco - Pau Brasil

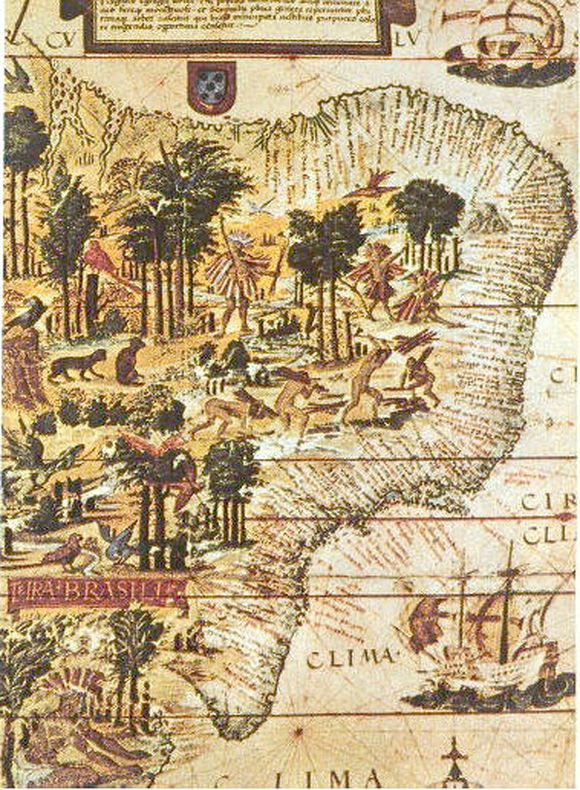

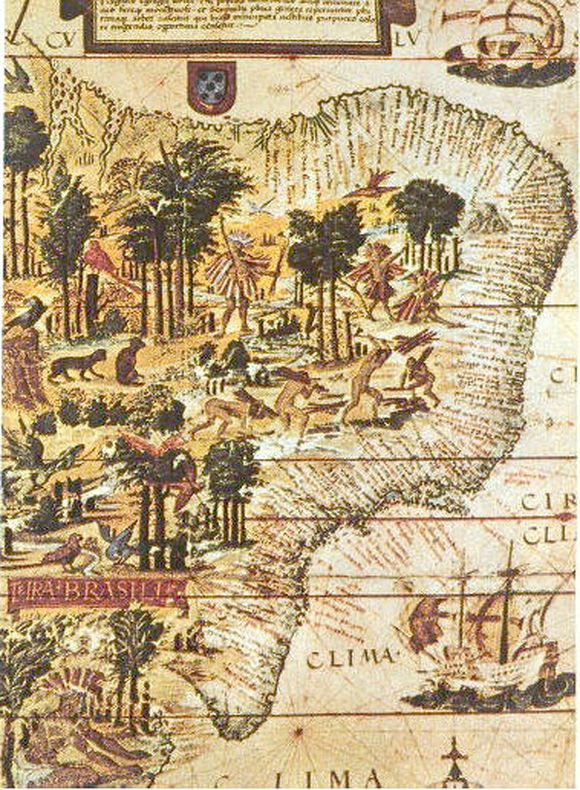

Native Americans used this wood for arrows and gained the red dye for their war paint. However, it wasn't until the 15th century that the Portuguese discovered this tree in Brazil ("Terra do Pau Brasil," hence the name Brazil) and noticed its red wood.

Brasil

Until the 17th century, this tree was mainly used for dyeing. Huge quantities were shipped to Europe due to the dye, resulting in a scarcity of this wood. It was Francois Xavier Tourte who, 200 years after the Europeans' discovery of the tree, built the first bow from Pernambuco wood, revolutionizing bow making.

Francois Xavier Tourte (1747 - 1835)

Manufacturing

During production, the stick is roughly cut longitudinally from the wood, then bent into shape using heat (up to 120 degrees). After cooling, the bent form remains, thanks to lignin, a substance found in many wood types. This process can be repeated indefinitely without damaging the wood.

Some bows have a round stick, while others have an octagonal stick. Bows with octagonal sticks are generally more expensive because their production is a bit more complex.

Stick

While the stick is responsible for stability and tension, the hair directly contacts the string. This contact surface consists of approximately 190 to 250 black or white horsehair from a gray horse. Horsehair is chosen for its roughness (under an electron microscope, tiny barbs can be seen).

The hair is securely fixed at the bow's tip and can be tightened to varying degrees on the other side using a screw.

Quick tip: If necessary, replacing bow hair should only be done by a specialized workshop; otherwise, the bow might suffer significant damage.

Various materials like silver, German silver (an alloy with nickel), or gold are used for the bow's fittings, contributing to quality and price differences.

Master bows often bear the maker's signature engraved above the frog.

Master bow

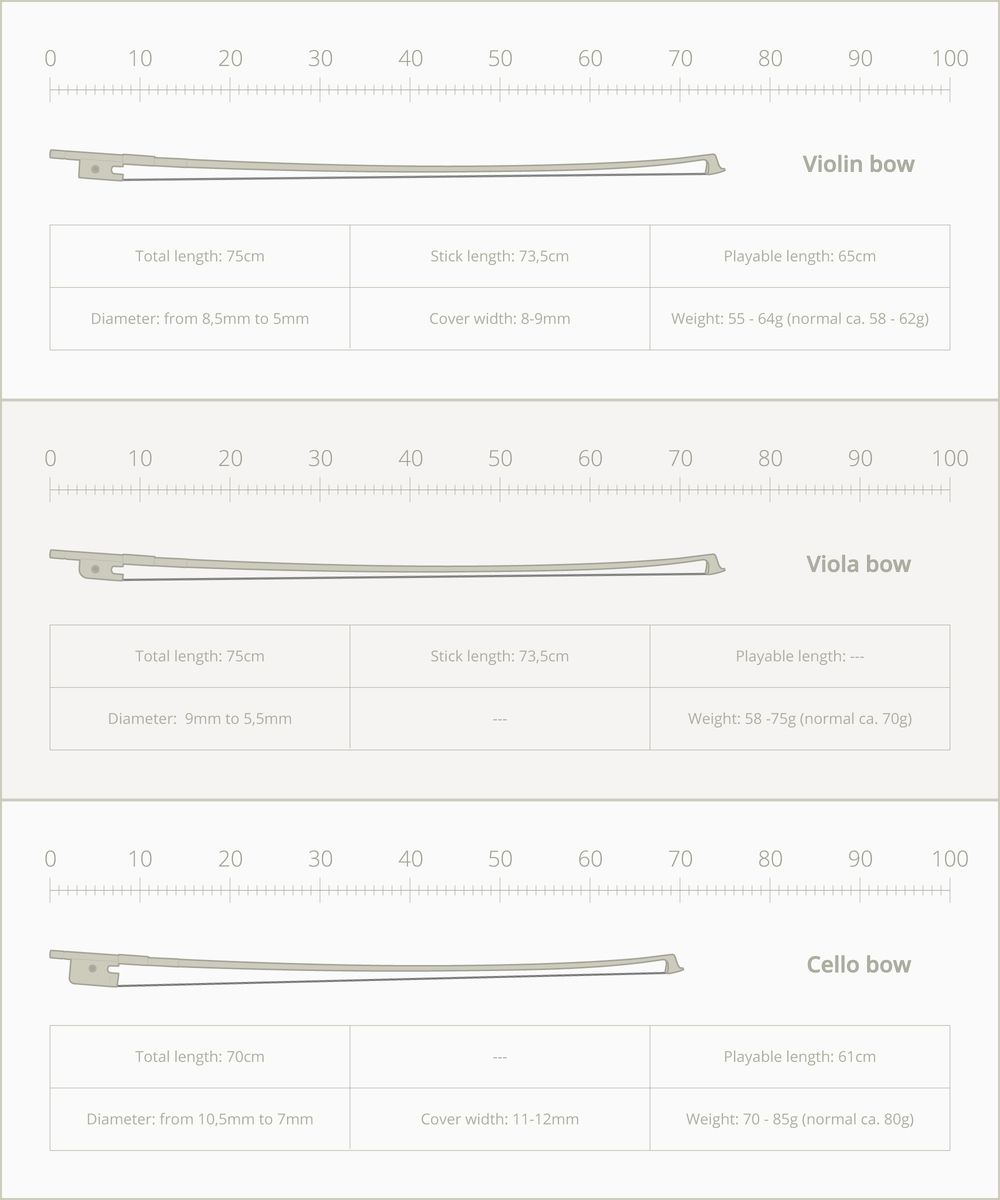

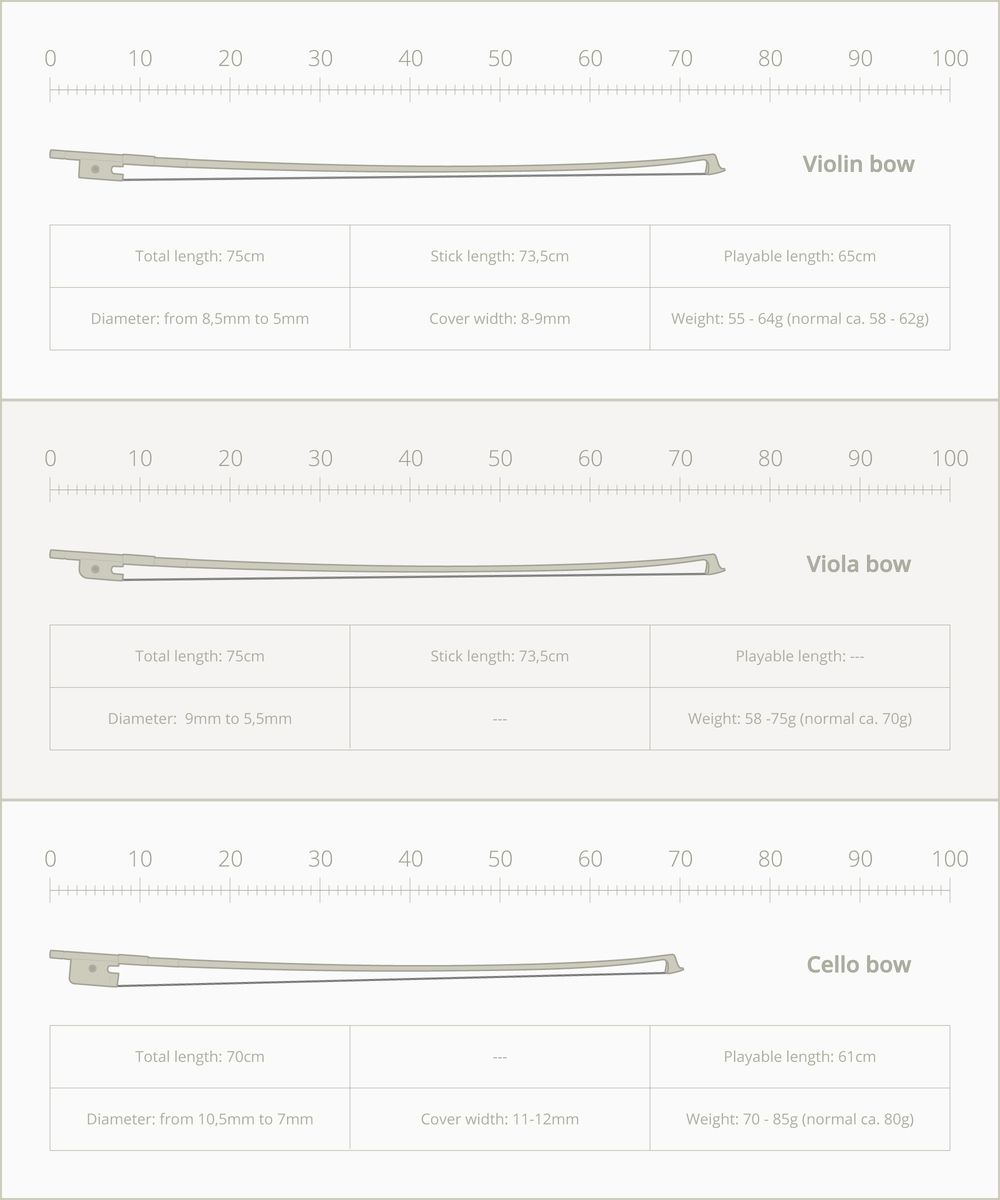

Finally, here's a list of the most common bow measurements.

Bow Measurements